Application

The choice of compressor for determined refrigeration equipment depends on two main factors.

1. CONTROL ELEMENT

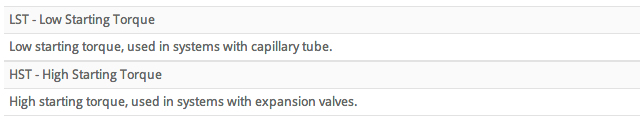

As we know, every refrigeration system needs a control element, which can be an expansion valve or a capillary tube. In circuits with a capillary tube, the pressures at the suction and discharge side equalize during compressor stop time. In this type of circuit, the compressor has a low starting torque motor.

Whereas a circuit with an expansion valve only has refrigerant flow through the valve while the compressor is running. Therefore, the pressures between the suction and discharge do not equalize. In this case, the compressor has a motor with high starting torque.

THE APPROPRIATE COMPRESSOR MOTORS FOR THESE TWO SYSTEMS ARE:

2. EVAPORATING TEMPERATURE

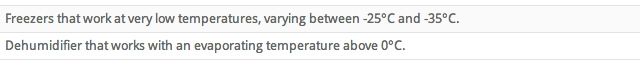

Another factor influencing the choice of compressor is the evaporating temperature range required by the system. Thus, we can cite two extremes:

The heat absorbed by the refrigerant will depend on the evaporating temperature.

A determined temperature in the evaporator will correspond to a determined pressure. Gas density is low in low temperatures and, therefore, only a small amount of heat can be absorbed during evaporation. If evaporation occurs at a higher temperature, e.g. 0°C, the pressure and density will increase and the amount of heat will be greater.

Due to this, we can conclude that the work done by a motor in a compressor will be greater than that done by the same compressor at a low evaporating temperature.

Consequently, motors for application in high evaporating pressure systems must have a higher running torque.

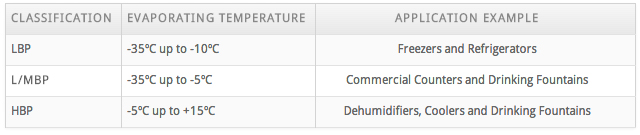

COMPRESSORS CAN BE CLASSIFIED ACCORDING TO THEIR APPLICATION:

When choosing a replacement model it is very important to know the type of compressor used in the original one. As you know, compressor running condition can vary according to each project. Thus, it is possible to have drinking fountains that require an HBP compressor while an L/MBP is applied to others.

CONDENSING UNITS:

Advance Technical Parts, the technology and market leader in hermetic refrigeration compressors reinforces its talent for innovation through its business unit Advance Technical Parts Cooling Solutions.

SEALED UNITS:

Partnership is the key word that translates to the pursuit of simple, innovative and exclusive solutions. A global structure of Engineering, Manufacturing and Laboratories ensures a quick response to customer requirements.

CONDENSING UNITS:

AVAILABLE FOR R 134A, R 404A/R 507, R 502, R 22 AND BLENDS.

• Designed for L/M/HBP application.

• Available with low and high starting torque and for tropical applications.

• Electrical connections designed for easy service.

• High thermodynamic performance.

• Customized design to meet specific requirements may include receiver and valves.

SEALED UNITS:

SPECIAL PROJECTS TO MEET CUSTOMER'S DIFFERENT NEEDS.

• Refrigerant charge included (ready-to-use system).

• It may include various accessories and all electrical connections necessary to operation.

Copyright©2014. Advance Technical Spare Parts Co. LLC. All rights reserved.

All the images used in this site are the property of ATP.

CONTACT

PRIVACY POLICY

CAREERS